8 Key Benefits of Compliance Management System in 2025

Feb 28, 2025

Regulations aren’t just red tape – they can make or break a manufacturer’s reputation.

A robust CMS unifies teams, automates audits, and translates dense mandates into tangible actions.

Instead of reacting to shifting standards, you’ll be ready for any inspection while unlocking real operational benefits.

In this post, we’ll explore how adopting a well-structured CMS can deliver genuine value beyond mere legal safety.

Why Compliance Matters More Than Ever

Manufacturing companies face a daunting array of regulations, from ISO standards like ISO 9001 (Quality Management), ISO 45001 (Occupational Health and Safety), and ISO 14001 (Environmental Management) to Good Manufacturing Practices (GMP) and even country-specific labor or environmental rules.

According to the National Association of Manufacturers (NAM), the average compliance costs for manufacturers in the U.S. are approximately $29,100 per employee per year.

For small manufacturers with fewer than 50 employees, this cost is significantly higher at $50,100 per employee per year.

The numbers can climb even higher if a company handles specialized products (e.g., pharmaceuticals or food).

Beyond regulations, modern consumers demand higher standards of quality, safety, and transparency.

Why Do You Need To Have CMS?

Global supply chains add further complexity, making compliance management a critical component of risk mitigation and brand protection.

In this environment, a Compliance Management System (CMS) is no longer a “nice-to-have”; it is a foundational tool for sustaining growth.

A CMS is an integrated platform or framework that helps you automate, track, and document compliance activities throughout your organization.

Instead of juggling spreadsheets, fragmented auditing systems, or paper-based documentation, a CMS offers a centralized repository and processes to ensure you’re meeting legal, ethical, and operational standards.

Below, we break down the major benefits of a CMS in manufacturing to illustrate how they can transform your operations.

Benefit #1: Streamlined Regulatory Compliance

Simplifying a Complex Landscape

Manufacturing environments typically need to comply with multiple regulations simultaneously – think FDA guidelines (for food and pharmaceuticals), GMPs, plus local rules and international ISO standards.

Managing such complexity manually can lead to oversight and the risk of incurring severe penalties.

A CMS centralizes all compliance-related data, making it easier to keep track of regulatory changes and ensure your processes align with the latest requirements.

Automated Audits and Documentation

A standout feature of many modern CMS solutions is automated documentation.

The system continuously logs relevant data (equipment maintenance, supplier certifications, employee training records), creating an audit trail that is readily available for inspections.

Rather than scrambling to compile information under tight deadlines, your audit requirements become a proactive, automated process.

For instance, automated solutions can save up to 95% of time and resources and speed up compliance processes by 89%.

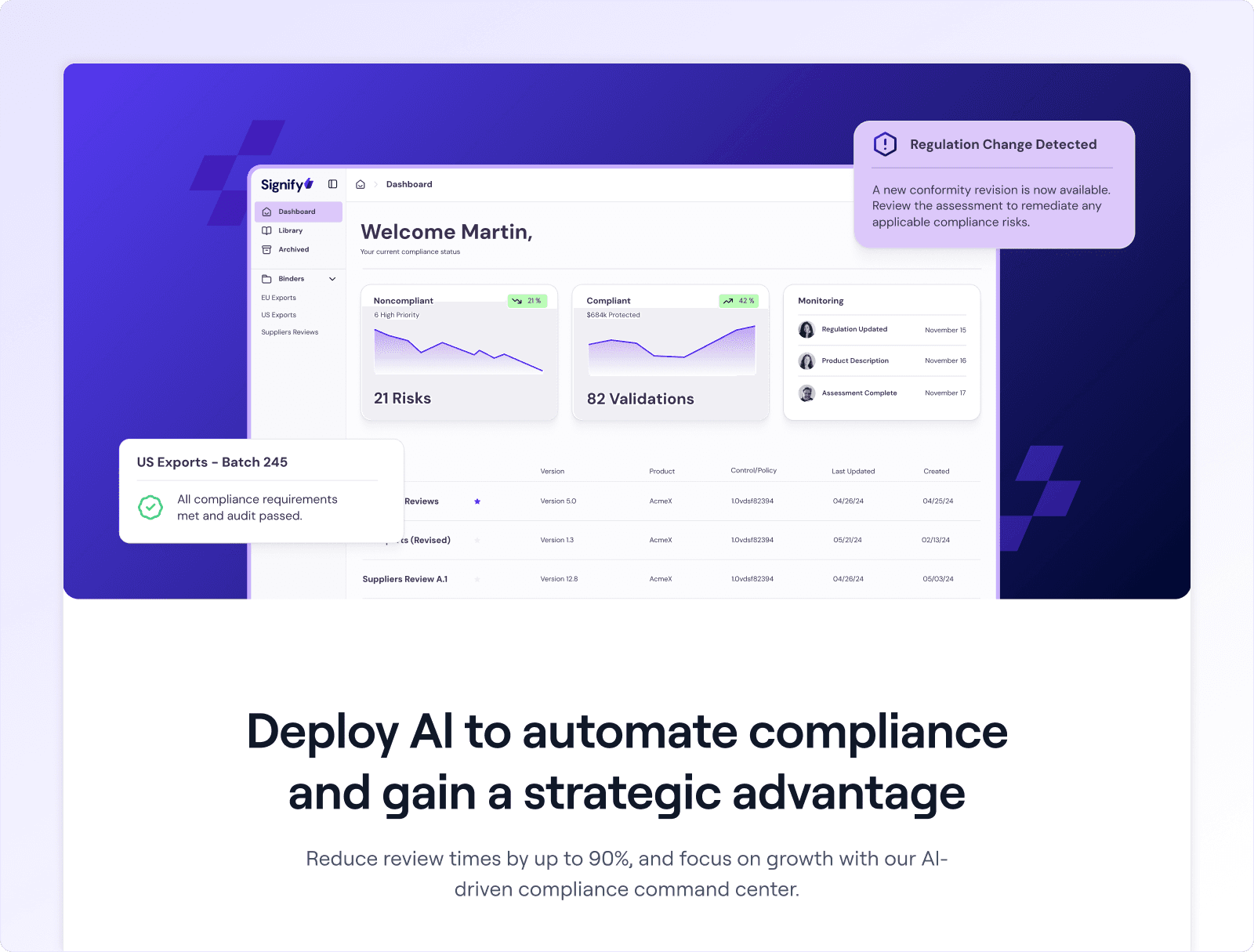

With Signify, compliance reviews that once took weeks are completed in hours – delivering greater accuracy while eliminating errors and omissions.

Standardized Processes Across the Board

When processes vary from one plant or region to another, inconsistencies in output quality and compliance can arise.

A CMS helps standardize operating procedures, aligning each plant or department with a unified compliance framework.

This not only reduces the likelihood of non-compliance but also promotes consistency in product quality.

For global manufacturers, ensuring uniform processes across multiple locations is essential to maintain brand integrity and meet diverse regulatory requirements.

Benefit #2: Proactive Risk Mitigation

Identifying and Prioritizing Risks

Compliance failures aren’t just about fines because they can also derail operations, damage reputations, and jeopardize customer relationships.

A robust CMS provides risk assessment tools that help you identify vulnerabilities, be it in equipment, supply chain quality, or employee training.

Through dashboards and data analytics, you can see where the highest-risk areas lie and allocate resources accordingly.

Pro Tip

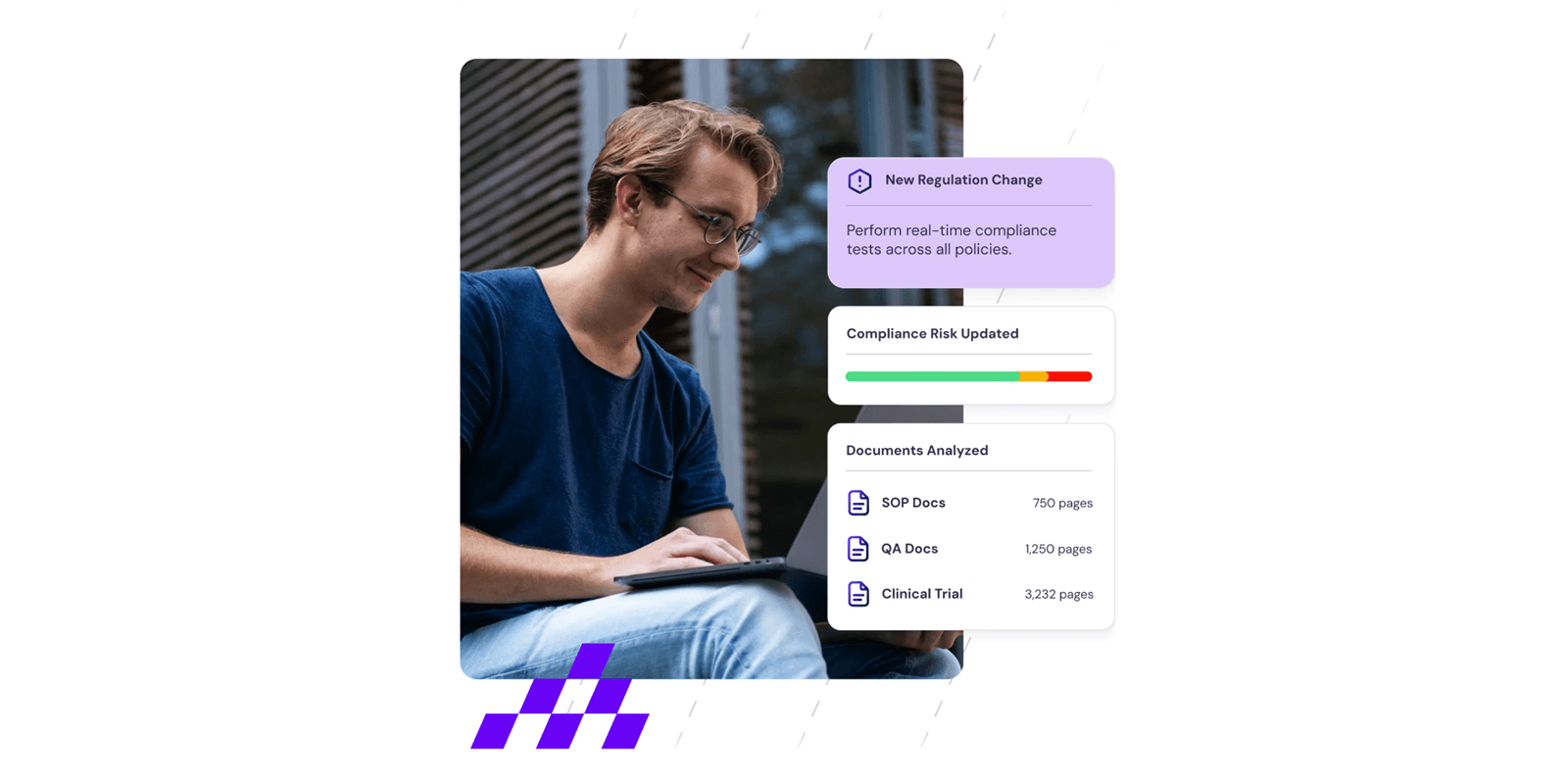

Signify takes the guesswork out of compliance by automatically reviewing documents in real-time, identifying risks without manual effort.

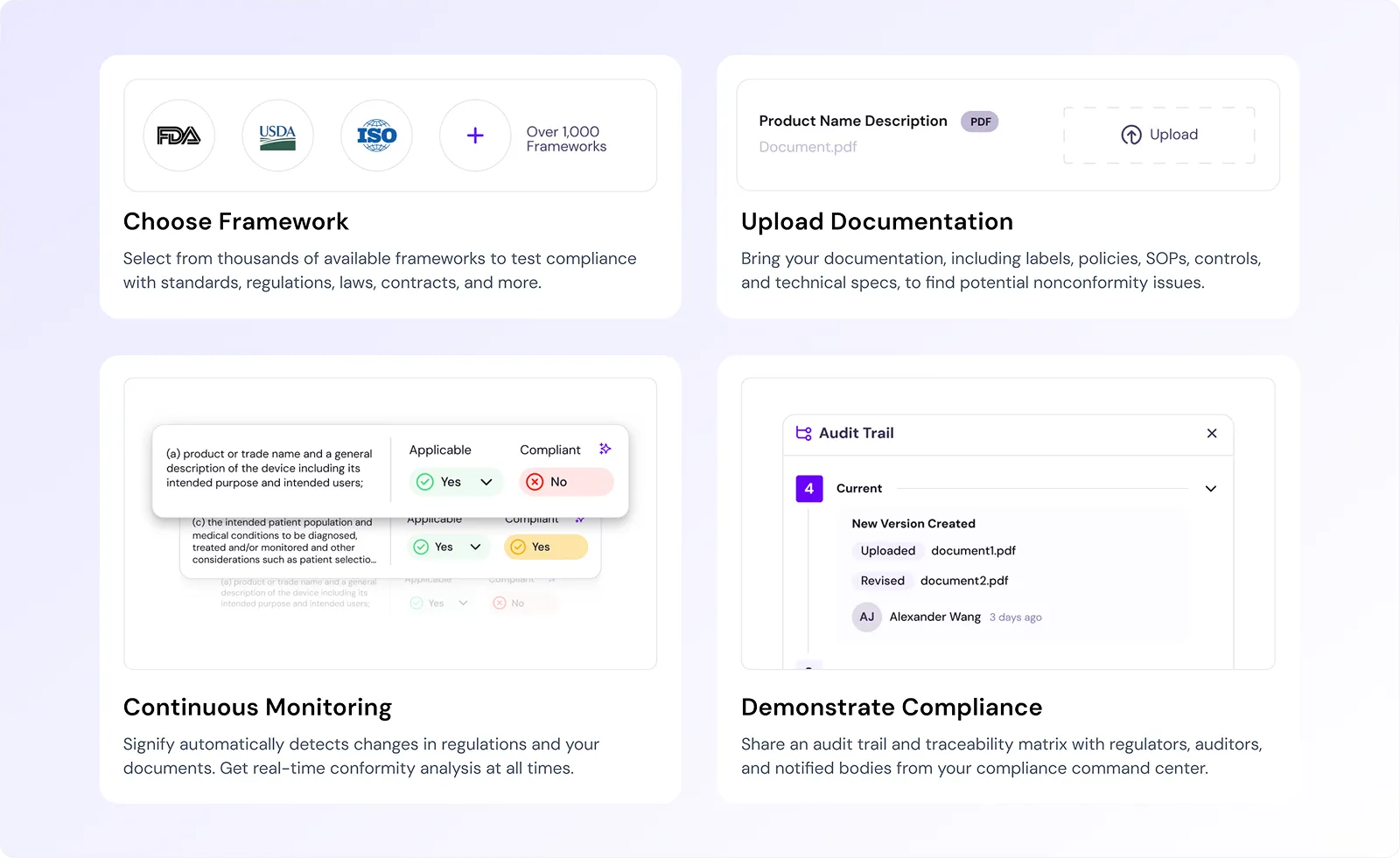

Choose Your Framework: Select from thousands of regulatory frameworks to instantly check compliance with laws, standards, and contracts.

Upload Documentation: Bring in your labels, SOPs, policies, and technical specs to uncover hidden nonconformities before they become problems.

Stay Ahead with Continuous Monitoring: Signify tracks regulatory updates and compares them against your documents, ensuring ongoing compliance without the manual chase.

Prove Compliance with Ease: Generate an audit-ready traceability matrix and share it effortlessly with regulators, auditors, or stakeholders, all from one central platform.

Real-Time Monitoring and Alerts

Many modern CMS platforms integrate with IoT (Internet of Things) devices on the factory floor, allowing you to monitor conditions like temperature, humidity, and machine performance in real-time.

If any parameter drifts outside acceptable ranges, the system sends an automated alert.

This capability is game-changing in industries like food manufacturing, where an out-of-range temperature can compromise product safety.

Reducing Legal Liabilities

Failing to spot a hazard or violation early can translate into expensive lawsuits or fines down the line.

With compliance monitoring system integrated into daily operations, you gain a proactive buffer against these liabilities.

Plus, demonstrating an established track record of proactive compliance can be a powerful defense should legal disputes arise.

Benefit #3: Enhanced Operational Efficiency

Automation of Repetitive Tasks

Beyond compliance, a well-configured CMS can automate or streamline an array of time-consuming tasks, such as document management, report generation, and approvals.

When you offload these tasks from employees, you free them up to focus on value-adding activities like process improvements or innovation.

Breaking Down Silos

Manufacturing often involves diverse functions – engineering, production, quality assurance, and supply chain management.

With a centralized compliance system, different teams can access the same real-time data and documents. This eliminates data silos and encourages cross-functional collaboration, which further optimizes production schedules, managing inventory efficiently, and responding swiftly to market demands.

Continuous Improvement Cycles

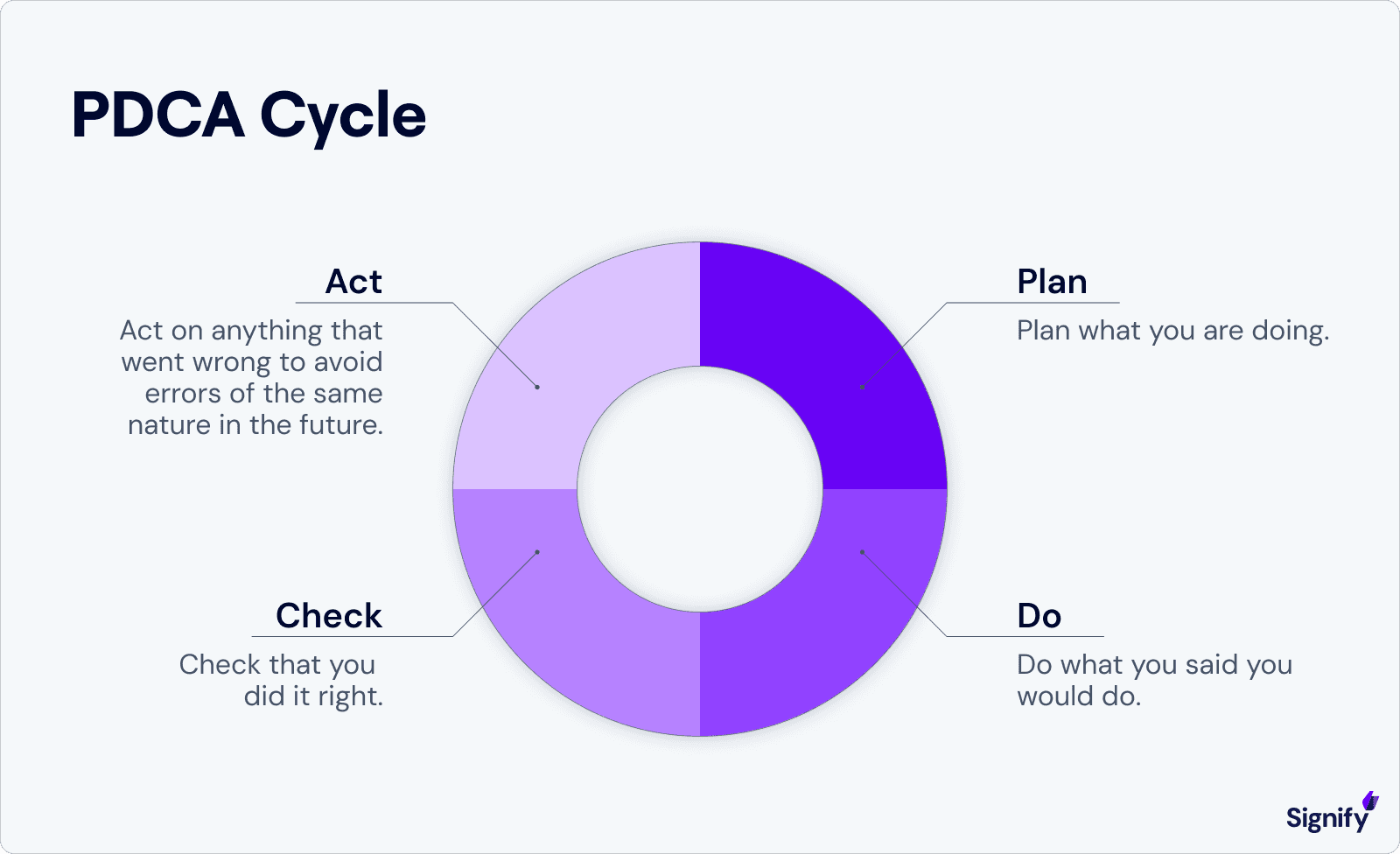

Systems like ISO 9001 already advocate for the “Plan-Do-Check-Act” methodology.

A CMS can enhance these cycles by providing ongoing metrics (non-conformance rates, audit outcomes, and employee training status) that reveal which processes are effective and which need refinement. This data-driven feedback loop is essential for continuous improvement.

Benefit #4: Culture of Accountability and Transparency

Clear Roles and Responsibilities

One underestimated benefit of a CMS is its role in cultural transformation within an organization. A robust system assigns clear tasks and responsibilities to each employee, from the shop floor worker to the compliance officer.

Everyone knows their role in maintaining compliance, thus creating a culture where accountability is woven into the fabric of daily operations.

Building Internal Champions

When employees see an integrated approach to compliance supported by user-friendly software, they’re more likely to champion safety, quality, and ethical standards.

Over time, the organization evolves from one that merely “checks boxes” to one where every staff member is invested in upholding and even improving compliance standards.

Benefit #5: Improved Reputation and Stakeholder Trust

Meeting Consumer Expectations

Consumer expectations for safe, ethically produced, and sustainable products continue to rise. A transparent CMS can demonstrate compliance with stringent industry standards and reassure customers about product quality.

This is especially pertinent in sectors like food manufacturing, where traceability from “farm to fork” is a growing requirement.

Stronger Relationships with Regulators

A history of compliance can pave the way for more constructive relationships with regulatory agencies.

When inspectors see evidence of a robust compliance framework, they’re more likely to view your company favorably, potentially easing the frequency or intensity of inspections.

Benefit #6: Data-Driven, Better Decision-Making

Centralized Data for Faster Insights

Effective decision-making in manufacturing depends on timely, accurate data.

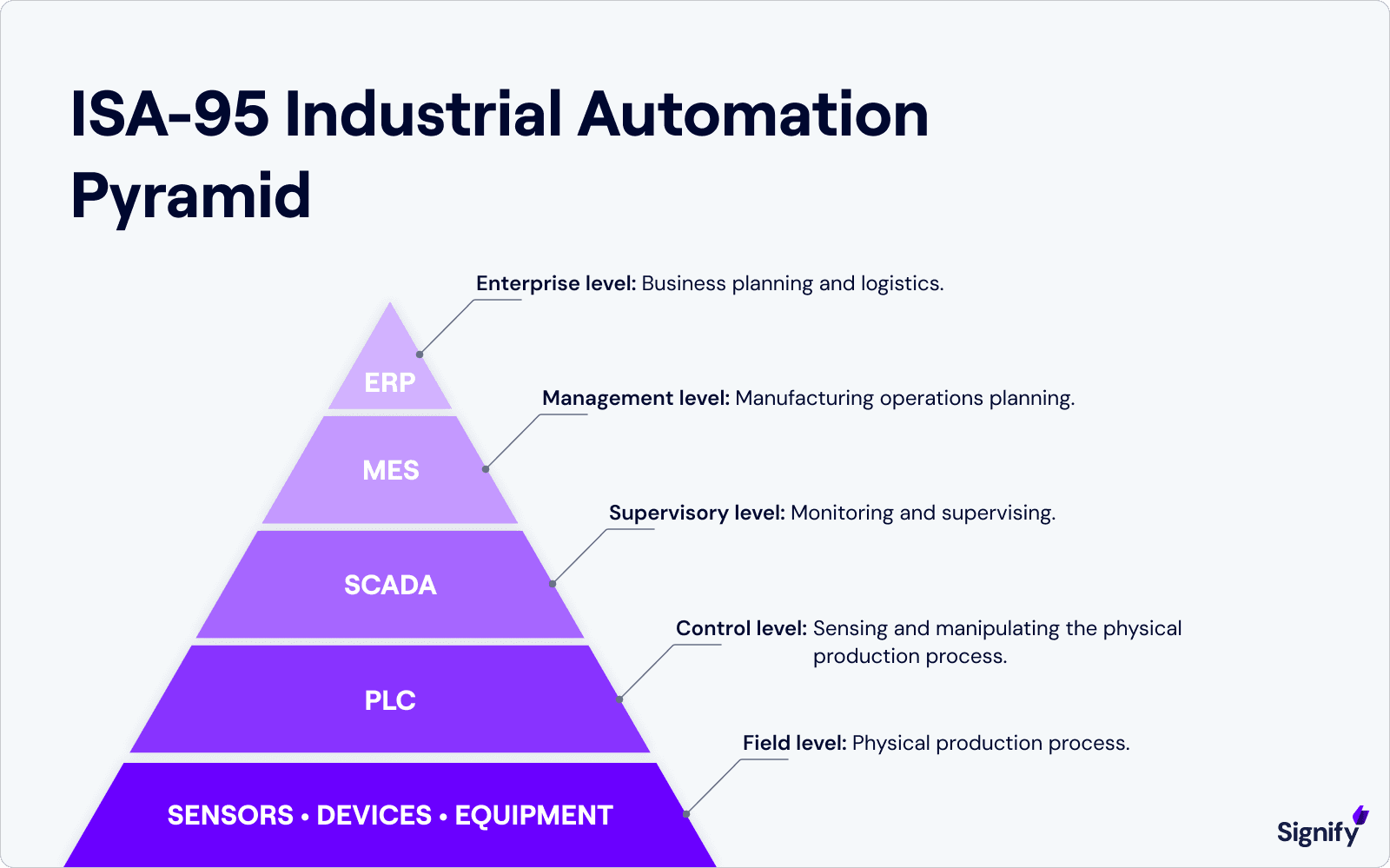

A modern CMS integrates with ERP (Enterprise Resource Planning) and MES (Manufacturing Execution System) platforms, centralizing not just compliance data, but also production schedules, equipment performance, and inventory levels.

This holistic data environment allows managers to quickly identify bottlenecks and opportunities for improvement.

Predictive Analytics and AI

Increasingly, CMS vendors offer modules powered by AI and machine learning.

Predictive analytics can pinpoint potential quality or compliance issues before they escalate.

For instance, if a particular machine’s sensor data regularly shows temperature fluctuations, the system can flag it for maintenance, preventing a possible compliance breach or production halt.

Benefit #7: Cost Savings and Better Resource Allocation

Lower Risk of Fines and Lawsuits

One of the most quantifiable benefits of a CMS is the avoidance of non-compliance penalties.

Regulatory fines can be steep, especially for repeated offenses.

Moreover, quality failures leading to product recalls can incur enormous costs, including the logistics of recall, legal fees, and reputational damage.

Reduced Waste and Improved Yield

A compliance-oriented framework often goes hand-in-hand with lean manufacturing principles.

In the food sector, a well-managed compliance system also curtails the risk of large-scale contamination and spoilage.

Fewer errors translate directly into cost savings, both in raw materials and labor.

Optimized Resource Planning

By identifying critical compliance needs and hotspots, management can allocate resources (time, budget, staff) to where they’re needed most.

A CMS’s reporting and analytics tools highlight trends and patterns, enabling proactive planning. For example, if a certain production line frequently fails safety audits, the system can guide the allocation of additional training or upgraded machinery to address the shortfall.

Benefit #8: Competitive Advantage and Growth Potential

Meeting Global Standards and Entering New Markets

If you aim to expand into international markets, demonstrating compliance with recognized standards (ISO, GMP, etc.) is often a prerequisite.

Many prospective clients or regulatory bodies require evidence of robust compliance frameworks before approving new partnerships or granting market access.

Driving Innovation

Paradoxically, tighter compliance requirements can spur innovation.

When you have a handle on your processes and clear data on every stage of production, it’s easier to explore new materials, production methods, or technologies.

When you leverage the insights from your CMS, you can test innovative ideas in a controlled environment, ensuring you remain compliant while pushing boundaries in product development.

Ready to Elevate Your Compliance Processes?

Signify delivers end-to-end compliance AI-powered automation that adapts to the challenges of modern food, beverage, and drug manufacturing.

By proactively identifying risks, automating documentation management, and offering real-time insights, Signify helps your organization stay on top of ever-shifting regulations while maintaining the highest quality standards.

Key Highlights Recap

Regulatory Compliance Intelligence: Automates conformance checks, minimizing manual oversight.

Radar Monitoring: Monitors global regulations and flags updates proactively.

Checklist Generator: Breaks down complex rules into straightforward action items.

Conformity Auditor: Continuously evaluates internal documents, policies, and product labeling.

Automated Compliance Testing: Keeps compliance checks ongoing and reduces reaction time to issues.

Remediation Guidance: Delivers instant corrective actions to close gaps quickly and efficiently.

Don’t let regulatory hurdles stand in the way of your growth or risk your brand’s reputation.

Book a Demo to see how Signify can help you automate regulatory processes, minimize compliance burdens, and maintain complete audit readiness – all while empowering your team to focus on product excellence and innovation.